In the fast-paced world of industrial packaging, ensuring secure, reliable, and cost-effective solutions for transporting and bundling goods is essential. Among the various strapping materials available, hot melt cord strap has emerged as an innovative and highly effective alternative to traditional steel banding. Combining the strength and durability of steel with enhanced flexibility and ease of application, hot melt cord strap offers a powerful solution for industries dealing with heavy-duty loads and challenging conditions.

Hot melt cord strap is a synthetic strapping material made from polyester or polypropylene fibers, reinforced with a layer of hot melt adhesive. When heated, the adhesive layer activates, allowing the strap to form a strong bond with the surface of the item being secured. This ultra-strong adhesive ensures that the strap maintains its grip even in high-stress environments. The core benefit of hot melt cord strap is its ability to combine the high tensile strength of traditional strapping materials with the flexibility of a cord-based design, making it ideal for a wide range of industrial applications.

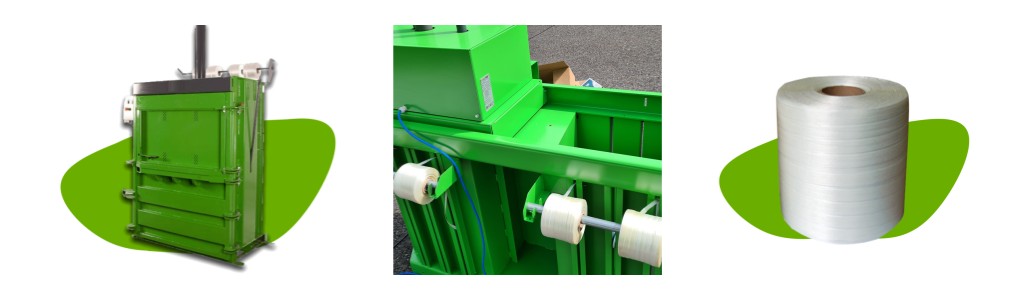

Available in various thicknesses, lengths, and strengths, hot melt cord strap is designed to meet the diverse needs of industries such as manufacturing, logistics, construction, and more. It can be used with standard strapping machines and tools, making it a versatile and user-friendly option for businesses.

High Strength and Load Capacity: Hot melt cord strap is known for its superior strength and impressive load capacity. Its robust structure allows it to handle even the heaviest and most demanding applications. Whether securing large bundles of materials, heavy machinery, or pallets, this strap provides the necessary strength to keep goods secure during transportation and storage.

Flexibility: One of the standout features of hot melt cord strap is its flexibility. Unlike steel banding, which can be rigid and prone to breakage, hot melt cord strap is flexible enough to wrap around irregular shapes and adjust to varying load sizes. This flexibility makes it ideal for securing items of different shapes, sizes, and weights, providing a reliable and adaptable solution for various industries.

Resistance to Harsh Conditions: Hot melt cord strap is engineered to withstand extreme conditions, including moisture, UV exposure, and temperature fluctuations. This makes it suitable for both indoor and outdoor applications. Whether used in outdoor storage, shipping, or industrial environments, this strap maintains its integrity and strength, ensuring secure bundling and transportation even in challenging weather conditions.

Ease of Application: One of the most notable advantages of hot melt cord strap is its ease of use. The adhesive layer activates when heated, and the strap can be applied quickly and efficiently with standard strapping machines. Unlike steel banding, which requires specialized tools and expertise, hot melt cord strap simplifies the strapping process, reducing labor costs and saving time. Additionally, it requires minimal maintenance, further enhancing its appeal for businesses looking to streamline their packaging operations.

Safety: Steel banding can pose significant safety risks due to its sharp edges and potential for injury. Hot melt cord strap, on the other hand, is smooth and flexible, reducing the risk of cuts and abrasions during application and handling. This makes it a safer alternative for workers and reduces the potential for accidents in the workplace.

Cost-Effective: While steel banding can be expensive and require specialized tools, hot melt cord strap is a more affordable option. It eliminates the need for costly buckles, tools, and maintenance, offering businesses a more cost-effective solution without sacrificing performance or reliability. Its durability and resistance to wear also mean that businesses save money by reducing the need for frequent replacements.

Hot melt cord strap is used across a wide range of industries where secure bundling and transportation are critical. Some common applications include:

Manufacturing and Logistics: Hot melt cord strap is widely used in manufacturing and logistics for securing bulk materials, machinery, and palletized goods. Its strength and adaptability make it ideal for bundling and securing products during transport, reducing the risk of damage.

Construction Industry: In the construction sector, hot melt cord strap is used to bundle heavy construction materials, including pipes, lumber, and steel. The flexibility and high load capacity ensure that the materials remain tightly bound, preventing shifting during transport.

Shipping and Warehousing: Hot melt cord strap is commonly used in shipping and warehousing environments to secure goods for long-distance transport. Its resistance to environmental factors such as moisture and UV exposure makes it an ideal choice for securing goods in outdoor storage or during extended transit periods.

Heavy Equipment: For industries that handle heavy machinery or large equipment, hot melt cord strap provides the strength necessary to secure these items during transportation or storage. Its high tensile strength ensures that even the heaviest loads stay securely in place.

Hot melt cord strap has quickly become a popular alternative to traditional steel banding due to its combination of strength, flexibility, and ease of use. Whether used in manufacturing, logistics, construction, or shipping, this resilient strapping solution provides a reliable and cost-effective way to secure heavy-duty loads in challenging conditions. With its impressive load capacity, resistance to harsh environments, and safety features, hot melt cord strap is set to remain a key tool for industries seeking efficient and secure packaging solutions.