In industries that handle heavy loads, ensuring the security of goods during transit is crucial. For years, steel banding was the go-to solution due to its high tensile strength and durability. However, the emergence of hot melt corded polyester strapping has revolutionized the strapping industry, offering a safer and more efficient alternative to steel.

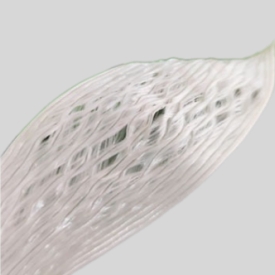

Hot melt corded polyester strapping, also known as flexible fiber strapping, is designed to provide a high break load capacity. This makes it ideal for securing heavy-duty loads such as lumber, steel coils, bricks, and machinery. Despite being lightweight, this type of strapping is exceptionally strong, with a break strength comparable to steel banding. The advanced polyester fibers used in its construction ensure consistent tension and load stability, even under extreme conditions.

One of the biggest advantages of polyester strapping over steel banding is its safety profile. Steel bands pose risks of sharp edges, which can lead to serious injuries during handling or cutting. In contrast, hot melt corded polyester strapping is soft and pliable, significantly reducing the risk of cuts or other accidents. Additionally, the strapping’s flexibility prevents damage to delicate or high-value goods, as it adapts to the shape of the product without leaving scratches or dents.

Unlike steel, which is prone to rust and corrosion, hot melt corded polyester strapping is resistant to environmental factors such as moisture, UV radiation, and temperature fluctuations. This makes it particularly suitable for outdoor storage and long-distance shipping, where goods may be exposed to varying weather conditions.

From an economic perspective, polyester strapping offers significant cost advantages. Its lightweight nature reduces shipping expenses and minimizes wear and tear on equipment. Furthermore, the strapping can be applied manually or with simple tensioning tools, eliminating the need for expensive machinery. Workers can secure loads efficiently, saving both time and labor costs.

In today’s eco-conscious world, the environmental impact of packaging materials is a growing concern. Hot melt corded polyester strapping is recyclable, making it a more sustainable choice compared to steel. Additionally, its production process consumes less energy, further reducing its carbon footprint.

The versatility of hot melt corded polyester strapping has made it a preferred choice across various industries. From construction and agriculture to logistics and manufacturing, businesses are adopting this innovative material to improve load security and operational efficiency.

Hot melt corded polyester strapping has emerged as a game-changer in the strapping industry. Its combination of strength, safety, and versatility makes it a superior alternative to traditional steel banding. By adopting this innovative solution, businesses can ensure the secure transportation of goods while enhancing workplace safety and reducing costs. As industries continue to evolve, the demand for advanced and eco-friendly strapping solutions like hot melt corded polyester strapping is set to rise, driving further innovation and growth in the market.