Corded hot melt strapping, also known as flexible composite strap, plays an indispensable role in the packaging and logistics industry. This high-performance consumable is widely used in vertical strapping machines, which are essential for securing goods in industries such as construction, manufacturing, and logistics. Its durability, versatility, and cost-effectiveness make it a preferred choice for businesses looking to enhance packaging efficiency and ensure the safety of their products during transport.

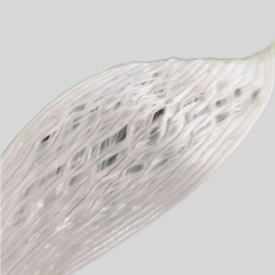

Corded hot melt strapping is known for its exceptional tensile strength and flexibility. Unlike traditional steel strapping, it offers a safer and lighter alternative while maintaining excellent load-securing capabilities. The strapping is coated with a high-friction adhesive layer that ensures a firm grip on various surfaces, preventing slippage during transit.

One of the key advantages of corded hot melt strapping is its resistance to corrosion and environmental factors. It remains effective even in humid or extreme temperature conditions, making it suitable for securing goods in diverse climates. Additionally, its lightweight nature reduces handling risks and improves worker safety, addressing one of the common concerns in the logistics sector.

Corded hot melt strapping is used extensively in industries requiring secure and reliable packaging. In the construction industry, it is commonly employed to bundle heavy materials like timber, steel rods, and bricks. Manufacturers use it to secure machinery, spare parts, and other heavy equipment. In logistics, it plays a critical role in unitizing pallets and securing loads for long-distance transportation, ensuring that goods arrive intact and undamaged.

The ease of use provided by vertical strapping machines enhances its application. These machines automate the process, saving time and labor while ensuring consistent tension and tightness. This feature is especially important for large-scale operations where speed and reliability are crucial.

As sustainability becomes a growing concern, corded hot melt strapping offers an eco-friendly alternative to traditional packaging materials. It is recyclable and requires less energy to produce compared to steel strapping, reducing the overall carbon footprint. Additionally, its reusability in certain applications contributes to waste reduction, aligning with global efforts toward sustainable packaging practices.

In conclusion, corded hot melt strapping is a vital consumable in modern packaging systems. Its combination of strength, flexibility, and environmental benefits makes it a valuable asset for industries worldwide. By integrating this advanced strapping solution with vertical strapping machines, businesses can optimize their packaging operations, improve product safety, and contribute to a more sustainable future.